ಕಸ್ಟಮ್ ಮೆಷಿನ್ಡ್ ಲೆಂಗ್ತ್ ಸ್ಟೀಲ್ ಆಂಗಲ್ ಕಟಿಂಗ್ ಸೇವೆಗಳು

ಉತ್ಪನ್ನದ ವಿವರ

ಉಕ್ಕಿನ ಸಂಸ್ಕರಿಸಿದ ಭಾಗಗಳು ಉಕ್ಕಿನ ಕಚ್ಚಾ ವಸ್ತುಗಳ ಆಧಾರದ ಮೇಲೆ, ಗ್ರಾಹಕರು ಒದಗಿಸಿದ ಉತ್ಪನ್ನ ರೇಖಾಚಿತ್ರಗಳ ಪ್ರಕಾರ, ಅಗತ್ಯವಿರುವ ಉತ್ಪನ್ನ ವಿಶೇಷಣಗಳು, ಆಯಾಮಗಳು, ವಸ್ತುಗಳು, ವಿಶೇಷ ಮೇಲ್ಮೈ ಚಿಕಿತ್ಸೆ ಮತ್ತು ಸಂಸ್ಕರಿಸಿದ ಭಾಗಗಳ ಇತರ ಮಾಹಿತಿಯ ಪ್ರಕಾರ ಗ್ರಾಹಕರಿಗೆ ಕಸ್ಟಮೈಸ್ ಮಾಡಿದ ಮತ್ತು ತಯಾರಿಸಿದ ಉತ್ಪನ್ನ ಉತ್ಪಾದನಾ ಅಚ್ಚುಗಳು. ಗ್ರಾಹಕರ ಅವಶ್ಯಕತೆಗಳಿಗೆ ಅನುಗುಣವಾಗಿ ನಿಖರತೆ, ಉತ್ತಮ-ಗುಣಮಟ್ಟದ ಮತ್ತು ಹೈಟೆಕ್ ಉತ್ಪಾದನೆಯನ್ನು ಕೈಗೊಳ್ಳಲಾಗುತ್ತದೆ. ಯಾವುದೇ ವಿನ್ಯಾಸ ರೇಖಾಚಿತ್ರಗಳಿಲ್ಲದಿದ್ದರೆ, ಪರವಾಗಿಲ್ಲ. ನಮ್ಮ ಉತ್ಪನ್ನ ವಿನ್ಯಾಸಕರು ಗ್ರಾಹಕರ ಅಗತ್ಯಗಳಿಗೆ ಅನುಗುಣವಾಗಿ ವಿನ್ಯಾಸಗೊಳಿಸುತ್ತಾರೆ.

ಸಂಸ್ಕರಿಸಿದ ಭಾಗಗಳ ಮುಖ್ಯ ವಿಧಗಳು:

ಬೆಸುಗೆ ಹಾಕಿದ ಭಾಗಗಳು, ರಂದ್ರ ಉತ್ಪನ್ನಗಳು, ಲೇಪಿತ ಭಾಗಗಳು, ಬಾಗಿದ ಭಾಗಗಳು, ಕತ್ತರಿಸುವ ಭಾಗಗಳು

ಲೋಹದ ಸಂಸ್ಕರಣೆ, ಯಂತ್ರೋಪಕರಣಗಳ ತಯಾರಿಕೆ, ಏರೋಸ್ಪೇಸ್ ಮತ್ತು ಇತರ ಕ್ಷೇತ್ರಗಳಲ್ಲಿ ಪ್ಲಾಸ್ಮಾ ಕತ್ತರಿಸುವಿಕೆಯನ್ನು ವ್ಯಾಪಕವಾಗಿ ಬಳಸಲಾಗುತ್ತದೆ. ಲೋಹದ ಸಂಸ್ಕರಣಾ ಕ್ಷೇತ್ರದಲ್ಲಿ, ಉಕ್ಕಿನ ಫಲಕಗಳು, ಅಲ್ಯೂಮಿನಿಯಂ ಮಿಶ್ರಲೋಹದ ಭಾಗಗಳು ಇತ್ಯಾದಿಗಳಂತಹ ವಿವಿಧ ಲೋಹದ ಭಾಗಗಳನ್ನು ಕತ್ತರಿಸಲು ಪ್ಲಾಸ್ಮಾ ಕತ್ತರಿಸುವಿಕೆಯನ್ನು ಬಳಸಬಹುದು, ಇದು ಭಾಗಗಳ ನಿಖರತೆ ಮತ್ತು ಗುಣಮಟ್ಟವನ್ನು ಖಚಿತಪಡಿಸುತ್ತದೆ. ಏರೋಸ್ಪೇಸ್ ಕ್ಷೇತ್ರದಲ್ಲಿ, ಎಂಜಿನ್ ಭಾಗಗಳು, ಫ್ಯೂಸ್ಲೇಜ್ ರಚನೆಗಳು ಇತ್ಯಾದಿಗಳಂತಹ ವಿಮಾನ ಭಾಗಗಳನ್ನು ಕತ್ತರಿಸಲು ಪ್ಲಾಸ್ಮಾ ಕತ್ತರಿಸುವಿಕೆಯನ್ನು ಬಳಸಬಹುದು, ಇದು ಭಾಗಗಳ ನಿಖರತೆ ಮತ್ತು ಹಗುರತೆಯನ್ನು ಖಚಿತಪಡಿಸುತ್ತದೆ.

ಸಂಕ್ಷಿಪ್ತವಾಗಿ ಹೇಳುವುದಾದರೆ, ಪ್ಲಾಸ್ಮಾ ಕತ್ತರಿಸುವುದು, ದಕ್ಷ ಮತ್ತು ಹೆಚ್ಚಿನ ನಿಖರತೆಯ ಕತ್ತರಿಸುವ ಸಂಸ್ಕರಣಾ ತಂತ್ರಜ್ಞಾನವಾಗಿ, ವಿಶಾಲವಾದ ಅಪ್ಲಿಕೇಶನ್ ನಿರೀಕ್ಷೆಗಳು ಮತ್ತು ಮಾರುಕಟ್ಟೆ ಬೇಡಿಕೆಯನ್ನು ಹೊಂದಿದೆ ಮತ್ತು ಭವಿಷ್ಯದ ಉತ್ಪಾದನಾ ಉದ್ಯಮದಲ್ಲಿ ಪ್ರಮುಖ ಪಾತ್ರ ವಹಿಸುತ್ತದೆ.

ತಯಾರಿಕೆಯಲ್ಲಿ ಲೇಸರ್ ಕಟ್ ಶೀಟ್ ಮೆಟಲ್ನ ಅನುಕೂಲಗಳು

ಉತ್ಪಾದನಾ ಜಗತ್ತಿನಲ್ಲಿ, ಉತ್ತಮ ಗುಣಮಟ್ಟದ ಉತ್ಪನ್ನಗಳನ್ನು ಉತ್ಪಾದಿಸುವಲ್ಲಿ ನಿಖರತೆ ಮತ್ತು ದಕ್ಷತೆಯು ಪ್ರಮುಖ ಅಂಶಗಳಾಗಿವೆ. ಇಲ್ಲಿಯೇ ಲೇಸರ್ ಕಟ್ ಶೀಟ್ ಮೆಟಲ್ ಕಾರ್ಯರೂಪಕ್ಕೆ ಬರುತ್ತದೆ, ಇದು ವಿವಿಧ ಕೈಗಾರಿಕೆಗಳಿಗೆ ವ್ಯಾಪಕ ಶ್ರೇಣಿಯ ಪ್ರಯೋಜನಗಳನ್ನು ನೀಡುತ್ತದೆ. ಆಟೋಮೋಟಿವ್ನಿಂದ ಏರೋಸ್ಪೇಸ್ವರೆಗೆ ಮತ್ತು ಎಲೆಕ್ಟ್ರಾನಿಕ್ಸ್ನಿಂದ ನಿರ್ಮಾಣದವರೆಗೆ, ಲೇಸರ್ ಕತ್ತರಿಸುವ ತಂತ್ರಜ್ಞಾನವು ಶೀಟ್ ಮೆಟಲ್ ಅನ್ನು ಸಂಸ್ಕರಿಸುವ ಮತ್ತು ಬಳಸುವ ವಿಧಾನದಲ್ಲಿ ಕ್ರಾಂತಿಯನ್ನುಂಟು ಮಾಡಿದೆ.

ಲೇಸರ್ ಕತ್ತರಿಸುವ ಶೀಟ್ ಮೆಟಲ್ ಅತ್ಯಂತ ನಿಖರತೆಯೊಂದಿಗೆ ವಸ್ತುಗಳನ್ನು ಕತ್ತರಿಸಲು ಹೆಚ್ಚಿನ ಶಕ್ತಿಯ ಲೇಸರ್ ಬಳಕೆಯನ್ನು ಒಳಗೊಂಡಿರುತ್ತದೆ. ಈ ಪ್ರಕ್ರಿಯೆಯು ಸಂಕೀರ್ಣ ವಿನ್ಯಾಸಗಳು ಮತ್ತು ಸಂಕೀರ್ಣ ಆಕಾರಗಳನ್ನು ಕನಿಷ್ಠ ವಸ್ತು ತ್ಯಾಜ್ಯದೊಂದಿಗೆ ಕತ್ತರಿಸಲು ಅನುವು ಮಾಡಿಕೊಡುತ್ತದೆ. ಉಕ್ಕು, ಅಲ್ಯೂಮಿನಿಯಂ ಮತ್ತು ತಾಮ್ರ ಸೇರಿದಂತೆ ವಿವಿಧ ಲೋಹಗಳನ್ನು ಕತ್ತರಿಸುವ ಸಾಮರ್ಥ್ಯವು ಲೇಸರ್ ಕತ್ತರಿಸುವಿಕೆಯನ್ನು ಅನೇಕ ಉತ್ಪಾದನಾ ಅಗತ್ಯಗಳಿಗೆ ಬಹುಮುಖ ಪರಿಹಾರವನ್ನಾಗಿ ಮಾಡುತ್ತದೆ.

ಲೇಸರ್ ಕಟ್ ಶೀಟ್ ಮೆಟಲ್ನ ಪ್ರಮುಖ ಅನುಕೂಲವೆಂದರೆ ಅದು ಒದಗಿಸುವ ಹೆಚ್ಚಿನ ಮಟ್ಟದ ನಿಖರತೆ. ಲೇಸರ್ ಕತ್ತರಿಸುವಿಕೆಯ ನಿಖರತೆಯು ಬಿಗಿಯಾದ ಸಹಿಷ್ಣುತೆಗಳು ಮತ್ತು ಸಂಕೀರ್ಣ ವಿವರಗಳನ್ನು ಸಾಧಿಸಲು ಅನುವು ಮಾಡಿಕೊಡುತ್ತದೆ, ಇದರ ಪರಿಣಾಮವಾಗಿ ಭಾಗಗಳು ಮತ್ತು ಘಟಕಗಳು ಸರಾಗವಾಗಿ ಒಟ್ಟಿಗೆ ಹೊಂದಿಕೊಳ್ಳುತ್ತವೆ. ಈ ಮಟ್ಟದ ನಿಖರತೆಯು ಕೈಗಾರಿಕೆಗಳಲ್ಲಿ ನಿರ್ಣಾಯಕವಾಗಿದೆ, ಅಲ್ಲಿ ಸಣ್ಣ ವಿಚಲನವು ಅಂತಿಮ ಉತ್ಪನ್ನದಲ್ಲಿ ಗಮನಾರ್ಹ ಸಮಸ್ಯೆಗಳಿಗೆ ಕಾರಣವಾಗಬಹುದು.

ಇದಲ್ಲದೆ, ಲೇಸರ್ ಕತ್ತರಿಸುವಿಕೆಯು ಸಾಂಪ್ರದಾಯಿಕ ವಿಧಾನಗಳಿಗೆ ಹೋಲಿಸಿದರೆ ಶೀಟ್ ಮೆಟಲ್ ಅನ್ನು ಸಂಸ್ಕರಿಸುವ ವೇಗವಾದ ಮತ್ತು ಹೆಚ್ಚು ಪರಿಣಾಮಕಾರಿ ವಿಧಾನವನ್ನು ನೀಡುತ್ತದೆ. CNC ತಂತ್ರಜ್ಞಾನದ ಬಳಕೆಯೊಂದಿಗೆ, ವಿನ್ಯಾಸಗಳನ್ನು ಕನಿಷ್ಠ ಸೆಟಪ್ ಸಮಯದೊಂದಿಗೆ ಪ್ರೋಗ್ರಾಮ್ ಮಾಡಬಹುದು ಮತ್ತು ಕಾರ್ಯಗತಗೊಳಿಸಬಹುದು, ಇದು ತ್ವರಿತ ಟರ್ನ್ಅರೌಂಡ್ ಸಮಯ ಮತ್ತು ಹೆಚ್ಚಿದ ಉತ್ಪಾದಕತೆಗೆ ಕಾರಣವಾಗುತ್ತದೆ. ಹೆಚ್ಚಿನ ಪ್ರಮಾಣದ ಉತ್ಪಾದನಾ ಅಗತ್ಯಗಳನ್ನು ಹೊಂದಿರುವ ಕೈಗಾರಿಕೆಗಳಿಗೆ ಇದು ವಿಶೇಷವಾಗಿ ಪ್ರಯೋಜನಕಾರಿಯಾಗಿದೆ.

ನಿಖರತೆ ಮತ್ತು ದಕ್ಷತೆಯ ಜೊತೆಗೆ, ಲೇಸರ್ ಕಟ್ ಶೀಟ್ ಮೆಟಲ್ ದೀರ್ಘಾವಧಿಯಲ್ಲಿ ವೆಚ್ಚ ಉಳಿತಾಯವನ್ನು ನೀಡುತ್ತದೆ. ಹೆಚ್ಚುವರಿ ಉಪಕರಣಗಳ ಅಗತ್ಯವಿಲ್ಲದೆ ಸಂಕೀರ್ಣ ವಿನ್ಯಾಸಗಳನ್ನು ಉತ್ಪಾದಿಸುವ ಸಾಮರ್ಥ್ಯದೊಂದಿಗೆ ವಸ್ತು ತ್ಯಾಜ್ಯದಲ್ಲಿನ ಕಡಿತವು ಕಡಿಮೆ ಉತ್ಪಾದನಾ ವೆಚ್ಚಗಳು ಮತ್ತು ತಯಾರಕರಿಗೆ ಒಟ್ಟಾರೆ ಉಳಿತಾಯಕ್ಕೆ ಕಾರಣವಾಗುತ್ತದೆ.

ಇದಲ್ಲದೆ, ಲೇಸರ್ ಕತ್ತರಿಸುವ ತಂತ್ರಜ್ಞಾನದ ನಮ್ಯತೆಯು ಸಾಂಪ್ರದಾಯಿಕ ಉಪಕರಣ ವಿಧಾನಗಳ ನಿರ್ಬಂಧಗಳಿಲ್ಲದೆ ಗ್ರಾಹಕೀಕರಣ ಮತ್ತು ಮೂಲಮಾದರಿಯನ್ನು ಅನುಮತಿಸುತ್ತದೆ. ಇದರರ್ಥ ತಯಾರಕರು ವಿನ್ಯಾಸ ಬದಲಾವಣೆಗಳಿಗೆ ತ್ವರಿತವಾಗಿ ಹೊಂದಿಕೊಳ್ಳಬಹುದು ಮತ್ತು ಗಮನಾರ್ಹ ಸೆಟಪ್ ವೆಚ್ಚಗಳನ್ನು ಮಾಡದೆಯೇ ಕಸ್ಟಮ್ ಭಾಗಗಳ ಸಣ್ಣ ಬ್ಯಾಚ್ಗಳನ್ನು ಉತ್ಪಾದಿಸಬಹುದು.

ಕೊನೆಯಲ್ಲಿ, ಉತ್ಪಾದನೆಯಲ್ಲಿ ಲೇಸರ್ ಕಟ್ ಶೀಟ್ ಮೆಟಲ್ನ ಅನುಕೂಲಗಳನ್ನು ನಿರಾಕರಿಸಲಾಗದು. ಅದರ ನಿಖರತೆ ಮತ್ತು ದಕ್ಷತೆಯಿಂದ ಹಿಡಿದು ವೆಚ್ಚ ಉಳಿತಾಯ ಮತ್ತು ನಮ್ಯತೆಯವರೆಗೆ, ಲೇಸರ್ ಕತ್ತರಿಸುವ ತಂತ್ರಜ್ಞಾನವು ಉತ್ತಮ ಗುಣಮಟ್ಟದ, ಕಸ್ಟಮ್ ಲೋಹದ ಭಾಗಗಳು ಮತ್ತು ಘಟಕಗಳನ್ನು ಬಯಸುವ ಕೈಗಾರಿಕೆಗಳಿಗೆ ಅನಿವಾರ್ಯ ಸಾಧನವಾಗಿದೆ. ತಂತ್ರಜ್ಞಾನವು ಮುಂದುವರೆದಂತೆ, ಉತ್ಪಾದನೆಯಲ್ಲಿ ಲೇಸರ್ ಕತ್ತರಿಸುವ ಸಾಮರ್ಥ್ಯವು ಬೆಳೆಯುತ್ತಲೇ ಇರುತ್ತದೆ, ಉದ್ಯಮಕ್ಕೆ ಇನ್ನಷ್ಟು ನವೀನ ಪರಿಹಾರಗಳನ್ನು ನೀಡುತ್ತದೆ.

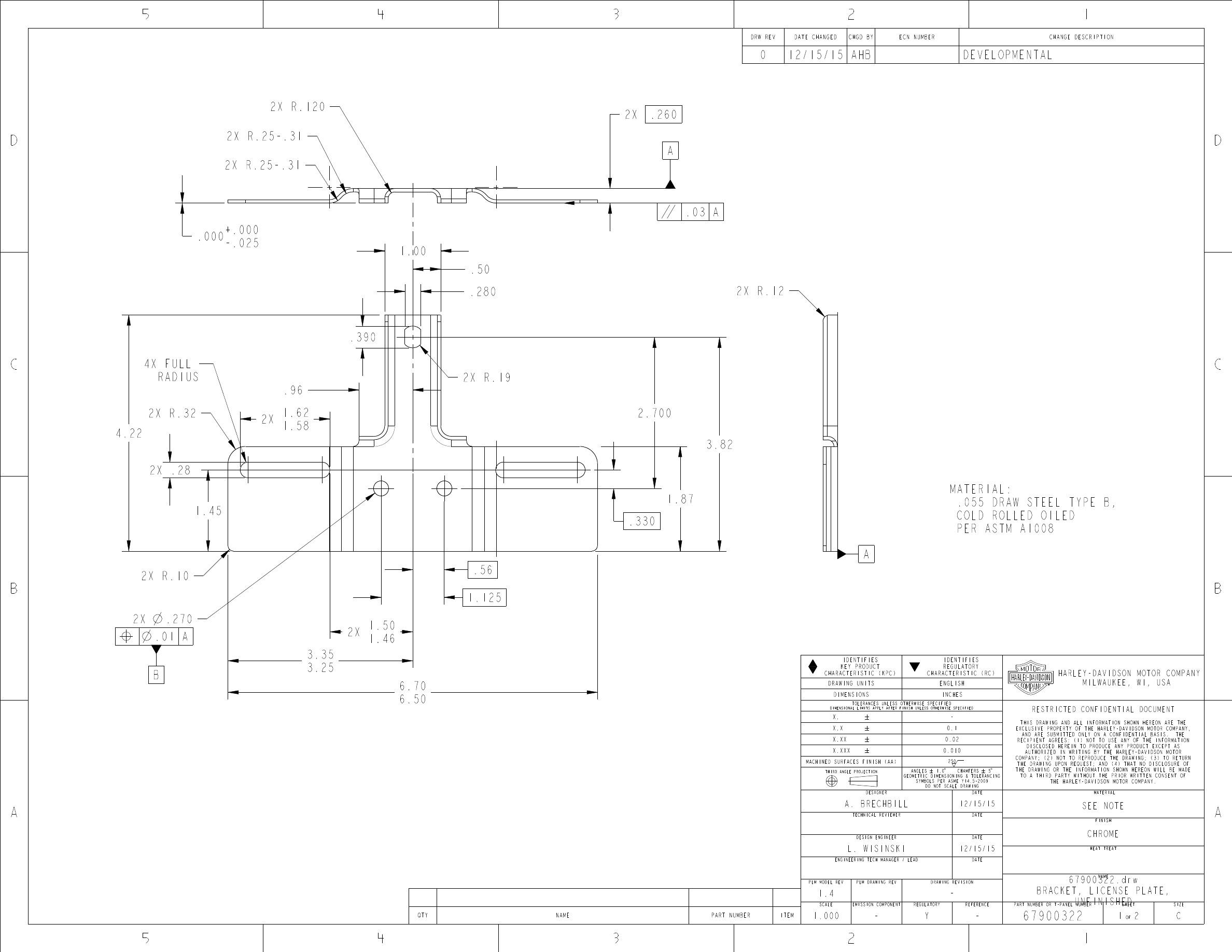

| ಕಸ್ಟಮ್ ನಿಖರ ಹಾಳೆ ಲೋಹದ ಫ್ಯಾಬ್ರಿಕೇಶನ್ ಭಾಗಗಳು | ||||

| ಉಲ್ಲೇಖ | ನಿಮ್ಮ ರೇಖಾಚಿತ್ರದ ಪ್ರಕಾರ (ಗಾತ್ರ, ವಸ್ತು, ದಪ್ಪ, ಸಂಸ್ಕರಣಾ ವಿಷಯ ಮತ್ತು ಅಗತ್ಯವಿರುವ ತಂತ್ರಜ್ಞಾನ, ಇತ್ಯಾದಿ) | |||

| ವಸ್ತು | ಕಾರ್ಬನ್ ಸ್ಟೀಲ್, ಸ್ಟೇನ್ಲೆಸ್ ಸ್ಟೀಲ್, SPCc, SGCc, ಪೈಪ್, ಕಲಾಯಿ | |||

| ಸಂಸ್ಕರಣೆ | ಲೇಸರ್ ಕತ್ತರಿಸುವುದು, ಬಾಗುವುದು, ರಿವರ್ಟಿಂಗ್, ಕೊರೆಯುವುದು, ವೆಲ್ಡಿಂಗ್, ಶೀಟ್ ಮೆಟಲ್ ರಚನೆ, ಜೋಡಣೆ, ಇತ್ಯಾದಿ. | |||

| ಮೇಲ್ಮೈ ಚಿಕಿತ್ಸೆ | ಹಲ್ಲುಜ್ಜುವುದು, ಹೊಳಪು ನೀಡುವುದು, ಅನೋಡೈಸಿಂಗ್, ಪೌಡರ್ ಲೇಪನ, ಲೇಪನ, | |||

| ಸಹಿಷ್ಣುತೆ | '+/- 0.2mm, ವಿತರಣೆಯ ಮೊದಲು 100% QC ಗುಣಮಟ್ಟದ ತಪಾಸಣೆ, ಗುಣಮಟ್ಟದ ತಪಾಸಣೆ ಫಾರ್ಮ್ ಅನ್ನು ಒದಗಿಸಬಹುದು | |||

| ಲೋಗೋ | ರೇಷ್ಮೆ ಮುದ್ರಣ, ಲೇಸರ್ ಗುರುತು | |||

| ಗಾತ್ರ/ಬಣ್ಣ | ಕಸ್ಟಮ್ ಗಾತ್ರಗಳು/ಬಣ್ಣಗಳನ್ನು ಸ್ವೀಕರಿಸುತ್ತದೆ | |||

| ರೇಖಾಚಿತ್ರ ಸ್ವರೂಪ | .DWG/.DXF/.STEP/.IGS/.3DS/.STL/.SKP/.AI/.PDF/.JPG/.ಡ್ರಾಫ್ಟ್ | |||

| ಮಾದರಿ ಊಟದ ಸಮಯ | ನಿಮ್ಮ ಅಗತ್ಯಗಳಿಗೆ ಅನುಗುಣವಾಗಿ ವಿತರಣಾ ಸಮಯವನ್ನು ಮಾತುಕತೆ ಮಾಡಿ | |||

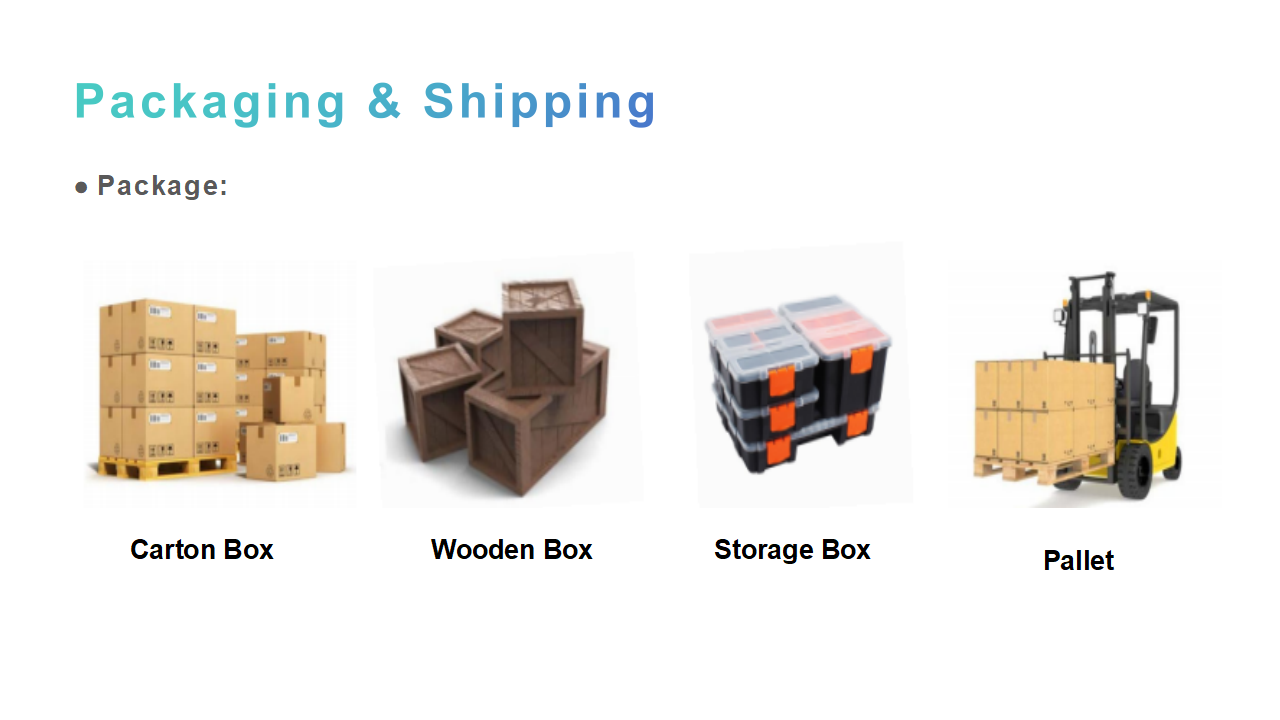

| ಪ್ಯಾಕಿಂಗ್ | ಕಾರ್ಟನ್/ಕ್ರೇಟ್ ಮೂಲಕ ಅಥವಾ ನಿಮ್ಮ ಅವಶ್ಯಕತೆಗೆ ಅನುಗುಣವಾಗಿ | |||

| ಪ್ರಮಾಣಪತ್ರ | ISO9001:SGS/TUV/ROHS | |||

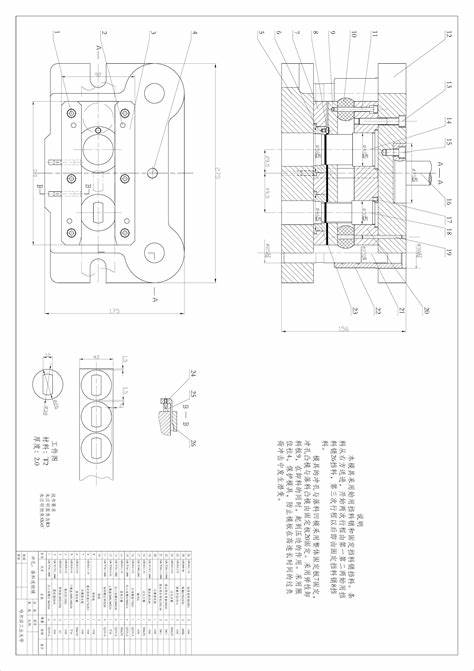

ಉದಾಹರಣೆ ನೀಡಿ

| ಕಸ್ಟಮ್ ಯಂತ್ರದ ಭಾಗಗಳು | |

| 1. ಗಾತ್ರ | ಕಸ್ಟಮೈಸ್ ಮಾಡಲಾಗಿದೆ |

| 2. ಪ್ರಮಾಣಿತ: | ಕಸ್ಟಮೈಸ್ ಮಾಡಲಾಗಿದೆ ಅಥವಾ GB |

| 3. ವಸ್ತು | ಕಸ್ಟಮೈಸ್ ಮಾಡಲಾಗಿದೆ |

| 4. ನಮ್ಮ ಕಾರ್ಖಾನೆಯ ಸ್ಥಳ | ಟಿಯಾಂಜಿನ್, ಚೀನಾ |

| 5. ಬಳಕೆ: | ಗ್ರಾಹಕರ ಸ್ವಂತ ಅಗತ್ಯಗಳನ್ನು ಪೂರೈಸಿಕೊಳ್ಳಿ |

| 6. ಲೇಪನ: | ಕಸ್ಟಮೈಸ್ ಮಾಡಲಾಗಿದೆ |

| 7. ತಂತ್ರ: | ಕಸ್ಟಮೈಸ್ ಮಾಡಲಾಗಿದೆ |

| 8. ಪ್ರಕಾರ: | ಕಸ್ಟಮೈಸ್ ಮಾಡಲಾಗಿದೆ |

| 9. ವಿಭಾಗದ ಆಕಾರ: | ಕಸ್ಟಮೈಸ್ ಮಾಡಲಾಗಿದೆ |

| 10. ಪರಿಶೀಲನೆ: | ಮೂರನೇ ವ್ಯಕ್ತಿಯಿಂದ ಕ್ಲೈಂಟ್ ತಪಾಸಣೆ ಅಥವಾ ತಪಾಸಣೆ. |

| 11. ವಿತರಣೆ: | ಕಂಟೇನರ್, ಬೃಹತ್ ಹಡಗು. |

| 12. ನಮ್ಮ ಗುಣಮಟ್ಟದ ಬಗ್ಗೆ: | 1) ಯಾವುದೇ ಹಾನಿ ಇಲ್ಲ, ಬಾಗಿಲ್ಲ 2) ನಿಖರವಾದ ಆಯಾಮಗಳು 3) ಎಲ್ಲಾ ಸರಕುಗಳನ್ನು ಸಾಗಣೆಗೆ ಮೊದಲು ಮೂರನೇ ವ್ಯಕ್ತಿಯ ತಪಾಸಣೆಯ ಮೂಲಕ ಪರಿಶೀಲಿಸಬಹುದು. |

ಮುಗಿದ ಉತ್ಪನ್ನ ಪ್ರದರ್ಶನ

ಪ್ಯಾಕೇಜಿಂಗ್ ಮತ್ತು ಶಿಪ್ಪಿಂಗ್

ಪ್ಲಾಸ್ಮಾ ಕಟ್ ಭಾಗಗಳ ಪ್ಯಾಕೇಜಿಂಗ್ ಮತ್ತು ಸಾಗಣೆಯು ಉತ್ಪನ್ನದ ಗುಣಮಟ್ಟ ಮತ್ತು ಸುರಕ್ಷಿತ ವಿತರಣೆಯನ್ನು ಖಚಿತಪಡಿಸಿಕೊಳ್ಳಲು ಪ್ರಮುಖ ಅಂಶಗಳಾಗಿವೆ. ಮೊದಲನೆಯದಾಗಿ, ಪ್ಲಾಸ್ಮಾ ಕತ್ತರಿಸುವ ಭಾಗಗಳಿಗೆ, ಅವುಗಳ ಹೆಚ್ಚಿನ ನಿಖರತೆ ಮತ್ತು ಉತ್ತಮ ಗುಣಮಟ್ಟದ ಕಾರಣ, ಸಾಗಣೆಯ ಸಮಯದಲ್ಲಿ ಹಾನಿಯನ್ನು ತಡೆಗಟ್ಟಲು ಸೂಕ್ತವಾದ ಪ್ಯಾಕೇಜಿಂಗ್ ವಸ್ತುಗಳು ಮತ್ತು ವಿಧಾನಗಳನ್ನು ಆಯ್ಕೆ ಮಾಡಬೇಕಾಗುತ್ತದೆ. ಸಣ್ಣ ಪ್ಲಾಸ್ಮಾ ಕತ್ತರಿಸುವ ಭಾಗಗಳಿಗೆ, ಅವುಗಳನ್ನು ಫೋಮ್ ಬಾಕ್ಸ್ಗಳು ಅಥವಾ ಪೆಟ್ಟಿಗೆಗಳಲ್ಲಿ ಪ್ಯಾಕ್ ಮಾಡಬಹುದು. ದೊಡ್ಡ ಪ್ಲಾಸ್ಮಾ ಕತ್ತರಿಸುವ ಭಾಗಗಳಿಗೆ, ಸಾಗಣೆಯ ಸಮಯದಲ್ಲಿ ಅವು ಹಾನಿಯಾಗದಂತೆ ನೋಡಿಕೊಳ್ಳಲು ಅವುಗಳನ್ನು ಸಾಮಾನ್ಯವಾಗಿ ಮರದ ಪೆಟ್ಟಿಗೆಗಳಲ್ಲಿ ಪ್ಯಾಕ್ ಮಾಡಬೇಕಾಗುತ್ತದೆ.

ಪ್ಯಾಕೇಜಿಂಗ್ ಪ್ರಕ್ರಿಯೆಯಲ್ಲಿ, ಪ್ಲಾಸ್ಮಾ ಕತ್ತರಿಸುವ ಭಾಗಗಳನ್ನು ಪ್ಲಾಸ್ಮಾ ಕತ್ತರಿಸುವ ಭಾಗಗಳ ಗುಣಲಕ್ಷಣಗಳಿಗೆ ಅನುಗುಣವಾಗಿ ಸಮಂಜಸವಾಗಿ ಸರಿಪಡಿಸಬೇಕು ಮತ್ತು ತುಂಬಬೇಕು, ಇದು ಸಾಗಣೆಯ ಸಮಯದಲ್ಲಿ ಘರ್ಷಣೆ ಮತ್ತು ಕಂಪನದಿಂದ ಉಂಟಾಗುವ ಹಾನಿಯನ್ನು ತಡೆಗಟ್ಟುತ್ತದೆ. ವಿಶೇಷ ಆಕಾರಗಳನ್ನು ಹೊಂದಿರುವ ಪ್ಲಾಸ್ಮಾ ಕಟ್ ಭಾಗಗಳಿಗೆ, ಸಾಗಣೆಯ ಸಮಯದಲ್ಲಿ ಅವು ಸ್ಥಿರವಾಗಿರುವುದನ್ನು ಖಚಿತಪಡಿಸಿಕೊಳ್ಳಲು ಕಸ್ಟಮೈಸ್ ಮಾಡಿದ ಪ್ಯಾಕೇಜಿಂಗ್ ಪರಿಹಾರಗಳನ್ನು ಸಹ ವಿನ್ಯಾಸಗೊಳಿಸಬೇಕಾಗುತ್ತದೆ.

ಸಾರಿಗೆ ಪ್ರಕ್ರಿಯೆಯಲ್ಲಿ, ಪ್ಲಾಸ್ಮಾ ಕತ್ತರಿಸುವ ಭಾಗಗಳನ್ನು ಸುರಕ್ಷಿತವಾಗಿ ಮತ್ತು ಸಮಯೋಚಿತವಾಗಿ ಗಮ್ಯಸ್ಥಾನಕ್ಕೆ ತಲುಪಿಸಬಹುದೆಂದು ಖಚಿತಪಡಿಸಿಕೊಳ್ಳಲು ವಿಶ್ವಾಸಾರ್ಹ ಲಾಜಿಸ್ಟಿಕ್ಸ್ ಪಾಲುದಾರರನ್ನು ಆಯ್ಕೆ ಮಾಡಬೇಕು. ಅಂತರರಾಷ್ಟ್ರೀಯ ಸಾರಿಗೆಗಾಗಿ, ಸುಗಮ ಕಸ್ಟಮ್ಸ್ ಕ್ಲಿಯರೆನ್ಸ್ ಮತ್ತು ವಿತರಣೆಯನ್ನು ಖಚಿತಪಡಿಸಿಕೊಳ್ಳಲು ನೀವು ಗಮ್ಯಸ್ಥಾನ ದೇಶದ ಸಂಬಂಧಿತ ಆಮದು ನಿಯಮಗಳು ಮತ್ತು ಸಾರಿಗೆ ಮಾನದಂಡಗಳನ್ನು ಸಹ ಅರ್ಥಮಾಡಿಕೊಳ್ಳಬೇಕು.

ಹೆಚ್ಚುವರಿಯಾಗಿ, ವಿಶೇಷ ವಸ್ತುಗಳು ಅಥವಾ ಸಂಕೀರ್ಣ ಆಕಾರಗಳಿಂದ ಮಾಡಿದ ಕೆಲವು ಪ್ಲಾಸ್ಮಾ ಕತ್ತರಿಸುವ ಭಾಗಗಳಿಗೆ, ಉತ್ಪನ್ನದ ಗುಣಮಟ್ಟವು ಪರಿಣಾಮ ಬೀರದಂತೆ ಖಚಿತಪಡಿಸಿಕೊಳ್ಳಲು ಪ್ಯಾಕೇಜಿಂಗ್ ಮತ್ತು ಸಾಗಣೆಯ ಸಮಯದಲ್ಲಿ ತೇವಾಂಶ-ನಿರೋಧಕ ಮತ್ತು ತುಕ್ಕು-ನಿರೋಧಕದಂತಹ ವಿಶೇಷ ಅವಶ್ಯಕತೆಗಳಿಗೆ ಗಮನ ಕೊಡಬೇಕಾಗುತ್ತದೆ.

ಒಟ್ಟಾರೆಯಾಗಿ ಹೇಳುವುದಾದರೆ, ಪ್ಲಾಸ್ಮಾ ಕತ್ತರಿಸುವ ಭಾಗಗಳ ಪ್ಯಾಕೇಜಿಂಗ್ ಮತ್ತು ಸಾಗಣೆಯು ಉತ್ಪನ್ನದ ಗುಣಮಟ್ಟ ಮತ್ತು ಗ್ರಾಹಕರ ತೃಪ್ತಿಯನ್ನು ಖಚಿತಪಡಿಸಿಕೊಳ್ಳಲು ಪ್ರಮುಖ ಕೊಂಡಿಗಳಾಗಿವೆ. ಉತ್ಪನ್ನವು ಸುರಕ್ಷಿತ ಮತ್ತು ಸಂಪೂರ್ಣವಾಗಿದೆ ಎಂದು ಖಚಿತಪಡಿಸಿಕೊಳ್ಳಲು ಪ್ಯಾಕೇಜಿಂಗ್ ವಸ್ತುಗಳ ಆಯ್ಕೆ, ಸ್ಥಿರ ಭರ್ತಿ, ಸಾರಿಗೆ ಆಯ್ಕೆ ಇತ್ಯಾದಿಗಳ ವಿಷಯದಲ್ಲಿ ಸಮಂಜಸವಾದ ಯೋಜನೆ ಮತ್ತು ಕಾರ್ಯಾಚರಣೆಗಳನ್ನು ಕೈಗೊಳ್ಳಬೇಕಾಗುತ್ತದೆ. ಗ್ರಾಹಕರಿಗೆ ತಲುಪಿಸಲಾಗುತ್ತದೆ.

ಕಂಪನಿಯ ಸಾಮರ್ಥ್ಯ

ಚೀನಾದಲ್ಲಿ ತಯಾರಿಸಲ್ಪಟ್ಟಿದೆ, ಪ್ರಥಮ ದರ್ಜೆ ಸೇವೆ, ಅತ್ಯಾಧುನಿಕ ಗುಣಮಟ್ಟ, ವಿಶ್ವಪ್ರಸಿದ್ಧ

1. ಸ್ಕೇಲ್ ಪರಿಣಾಮ: ನಮ್ಮ ಕಂಪನಿಯು ದೊಡ್ಡ ಪೂರೈಕೆ ಸರಪಳಿ ಮತ್ತು ದೊಡ್ಡ ಉಕ್ಕಿನ ಕಾರ್ಖಾನೆಯನ್ನು ಹೊಂದಿದ್ದು, ಸಾರಿಗೆ ಮತ್ತು ಸಂಗ್ರಹಣೆಯಲ್ಲಿ ಪ್ರಮಾಣದ ಪರಿಣಾಮಗಳನ್ನು ಸಾಧಿಸುತ್ತದೆ ಮತ್ತು ಉತ್ಪಾದನೆ ಮತ್ತು ಸೇವೆಗಳನ್ನು ಸಂಯೋಜಿಸುವ ಉಕ್ಕಿನ ಕಂಪನಿಯಾಗಿದೆ.

2. ಉತ್ಪನ್ನ ವೈವಿಧ್ಯತೆ: ಉತ್ಪನ್ನ ವೈವಿಧ್ಯತೆ, ನೀವು ಬಯಸುವ ಯಾವುದೇ ಉಕ್ಕನ್ನು ನಮ್ಮಿಂದ ಖರೀದಿಸಬಹುದು, ಮುಖ್ಯವಾಗಿ ಉಕ್ಕಿನ ರಚನೆಗಳು, ಉಕ್ಕಿನ ಹಳಿಗಳು, ಉಕ್ಕಿನ ಹಾಳೆ ರಾಶಿಗಳು, ದ್ಯುತಿವಿದ್ಯುಜ್ಜನಕ ಆವರಣಗಳು, ಚಾನಲ್ ಉಕ್ಕು, ಸಿಲಿಕಾನ್ ಉಕ್ಕಿನ ಸುರುಳಿಗಳು ಮತ್ತು ಇತರ ಉತ್ಪನ್ನಗಳಲ್ಲಿ ತೊಡಗಿಸಿಕೊಂಡಿದೆ, ಇದು ಹೆಚ್ಚು ಹೊಂದಿಕೊಳ್ಳುವಂತೆ ಮಾಡುತ್ತದೆ. ವಿಭಿನ್ನ ಅಗತ್ಯಗಳನ್ನು ಪೂರೈಸಲು ಬಯಸಿದ ಉತ್ಪನ್ನ ಪ್ರಕಾರವನ್ನು ಆರಿಸಿ.

3. ಸ್ಥಿರ ಪೂರೈಕೆ: ಹೆಚ್ಚು ಸ್ಥಿರವಾದ ಉತ್ಪಾದನಾ ಮಾರ್ಗ ಮತ್ತು ಪೂರೈಕೆ ಸರಪಳಿಯನ್ನು ಹೊಂದಿರುವುದು ಹೆಚ್ಚು ವಿಶ್ವಾಸಾರ್ಹ ಪೂರೈಕೆಯನ್ನು ಒದಗಿಸುತ್ತದೆ. ಹೆಚ್ಚಿನ ಪ್ರಮಾಣದ ಉಕ್ಕಿನ ಅಗತ್ಯವಿರುವ ಖರೀದಿದಾರರಿಗೆ ಇದು ಮುಖ್ಯವಾಗಿದೆ.

4. ಬ್ರ್ಯಾಂಡ್ ಪ್ರಭಾವ: ಹೆಚ್ಚಿನ ಬ್ರ್ಯಾಂಡ್ ಪ್ರಭಾವ ಮತ್ತು ದೊಡ್ಡ ಮಾರುಕಟ್ಟೆಯನ್ನು ಹೊಂದಿರಿ

5. ಸೇವೆ: ಗ್ರಾಹಕೀಕರಣ, ಸಾಗಣೆ ಮತ್ತು ಉತ್ಪಾದನೆಯನ್ನು ಸಂಯೋಜಿಸುವ ದೊಡ್ಡ ಉಕ್ಕಿನ ಕಂಪನಿ.

6. ಬೆಲೆ ಸ್ಪರ್ಧಾತ್ಮಕತೆ: ಸಮಂಜಸವಾದ ಬೆಲೆ

ಗ್ರಾಹಕರ ಭೇಟಿ

ಪದೇ ಪದೇ ಕೇಳಲಾಗುವ ಪ್ರಶ್ನೆಗಳು

1. ನಿಮ್ಮಿಂದ ನಾನು ಹೇಗೆ ಉದ್ಧರಣ ಪಡೆಯಬಹುದು?

ನೀವು ನಮಗೆ ಸಂದೇಶ ಕಳುಹಿಸಬಹುದು, ಮತ್ತು ನಾವು ಪ್ರತಿ ಸಂದೇಶಕ್ಕೂ ಸಮಯಕ್ಕೆ ಉತ್ತರಿಸುತ್ತೇವೆ.

2. ನೀವು ಸಮಯಕ್ಕೆ ಸರಿಯಾಗಿ ಸರಕುಗಳನ್ನು ತಲುಪಿಸುತ್ತೀರಾ?

ಹೌದು, ನಾವು ಉತ್ತಮ ಗುಣಮಟ್ಟದ ಉತ್ಪನ್ನಗಳನ್ನು ಮತ್ತು ಸಮಯಕ್ಕೆ ಸರಿಯಾಗಿ ವಿತರಣೆಯನ್ನು ಒದಗಿಸುತ್ತೇವೆ ಎಂದು ಭರವಸೆ ನೀಡುತ್ತೇವೆ. ಪ್ರಾಮಾಣಿಕತೆ ನಮ್ಮ ಕಂಪನಿಯ ತತ್ವ.

3. ಆರ್ಡರ್ ಮಾಡುವ ಮೊದಲು ನಾನು ಮಾದರಿಗಳನ್ನು ಪಡೆಯಬಹುದೇ?

ಹೌದು, ಖಂಡಿತ. ಸಾಮಾನ್ಯವಾಗಿ ನಮ್ಮ ಮಾದರಿಗಳು ಉಚಿತ, ನಿಮ್ಮ ಮಾದರಿಗಳು ಅಥವಾ ತಾಂತ್ರಿಕ ರೇಖಾಚಿತ್ರಗಳ ಮೂಲಕ ನಾವು ಉತ್ಪಾದಿಸಬಹುದು.

4.ನಿಮ್ಮ ಪಾವತಿ ನಿಯಮಗಳು ಯಾವುವು?

ನಮ್ಮ ಸಾಮಾನ್ಯ ಪಾವತಿ ಅವಧಿಯು 30% ಠೇವಣಿ, ಮತ್ತು ಉಳಿದ ಅವಧಿಯು B/L ಮೇಲೆ.

5. ನೀವು ಮೂರನೇ ವ್ಯಕ್ತಿಯ ತಪಾಸಣೆಯನ್ನು ಸ್ವೀಕರಿಸುತ್ತೀರಾ?

ಹೌದು, ಖಂಡಿತ ನಾವು ಒಪ್ಪಿಕೊಳ್ಳುತ್ತೇವೆ.

6.ನಿಮ್ಮ ಕಂಪನಿಯನ್ನು ನಾವು ಹೇಗೆ ನಂಬುತ್ತೇವೆ?

ನಾವು ಉಕ್ಕಿನ ವ್ಯವಹಾರದಲ್ಲಿ ವರ್ಷಗಳಿಂದ ಪರಿಣತಿ ಹೊಂದಿದ್ದೇವೆ, ಚಿನ್ನದ ಪೂರೈಕೆದಾರರಾಗಿ, ಪ್ರಧಾನ ಕಚೇರಿ ಟಿಯಾಂಜಿನ್ ಪ್ರಾಂತ್ಯದಲ್ಲಿದೆ, ಯಾವುದೇ ರೀತಿಯಲ್ಲಿ, ಎಲ್ಲಾ ವಿಧಾನಗಳಿಂದ ತನಿಖೆ ಮಾಡಲು ಸ್ವಾಗತ.